1. In practical use of the line for capsulation one person is engaged in preparation of gelatinous weight. Gelatin preparation time - 1 - 1,5 hour. At the beginning of each change (morning of each working day) gelatinous weight, at the rate of 7 liters of ready weight on 7 business hours of installation prepares. Equipment for gelatin preparation. Gelatin is prepared on a steam bath with a temperature + by 60 degrees. It can be any ware adapted for this purpose. Task: on a steam bath to mix gelatin at a temperature of +60 degrees before full swelling.

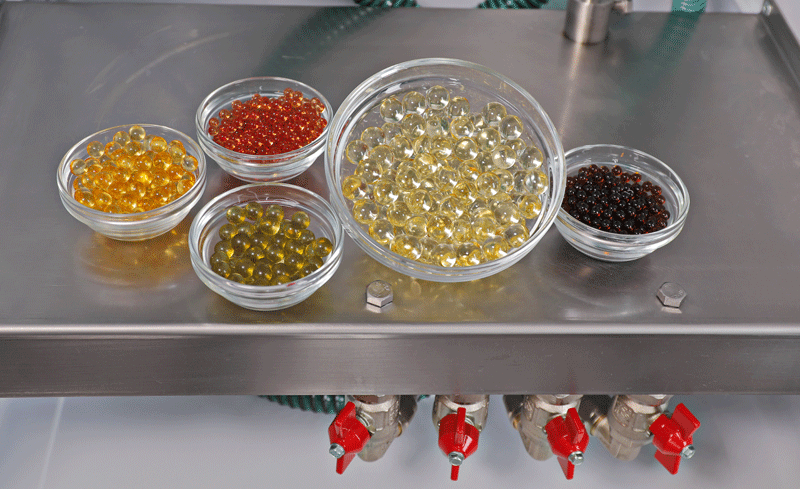

2. In any suitable ware you mix capsule substance-filler.

3. Requirements to the room - maintenance of constant air temperature in the range from + 15 to + 25 degrees. This purpose will require any good conditioner of air with the moisture separator. In the Encapsulator system oil is filled in. Usually food (for transportation of softgel softgel capsules in system). In practice use olive or sunflower oil. At high humidity oil incorporates water, grows turbid and does not become suitable for use in a kapsulyator. Further in the same room there is also a kapsulyation. Ready softgel softgel capsules get to special reception trays with oil. Several trays baking sheets with height of walls of 50 mm, overall dimensions - according to productivity are required. 400 mm by 400 mm. Are made of food stainless steel. Softgel Softgel capsules with a speed of 5 pieces a second get to oil on Protvino. As soon as the tray a baking sheet is filled adequately, it is placed in the room with the name "REFRIGERATOR". Requirements to "refrigerator" constant temperature + 10 degrees. It can be also specially equipped room, and ordinary refrigerators. It is required to place in these refrigerators all trays - baking sheets with softgel softgel capsules which will be made for change. In "REFRIGERATOR" softgel softgel capsules cool down (working temperature of gelatin in a kapsulyator + 60 degrees). There is a process - gelatin FIXING. Term necessary for fixing of softgel softgel capsules 1 days. When planning it is required to consider that next day it is necessary to fix new softgel softgel capsules in other "refrigerators".

4. Our WERE FIXED softgel softgel capsules in oil at a temperature + 10 degrees, time to merge oil in a day comes. Any centrifuge as option - the top-loaded washing machine and an extraction will be suitable for these purposes. The indispensable condition at selection of the washing machine with the centrifuge - a drum from stainless steel and diameter of openings in a drum does not exceed diameter of softgel softgel capsules. For an extraction it is enough to buy only 1 washing machine. Filled a drum, included an extraction and in 4 - 7 seconds the batch of softgel softgel capsules is wrung out.

5. At once after an extraction of oil of the capsule display on big baking sheets for drying. These baking sheets should not have high walls, and have to place on themselves as it is possible more freely our gelatin softgel softgel capsules. Softgel Softgel capsules when drying should not adjoin with each other and not lie one on one. The room for drying too with the conditioner. Temperature from + 20 to + 28 degrees, the level of humidity is no more than 50%. The corresponding conditioner will be required (already the third). Special racks for baking sheets will be required. Process of drying has to be stream, in one corner a rack with the first party in another with fresh, etc. Time of drying of softgel softgel capsules - 1 days. Special paper for a laying between softgel softgel capsules and a baking sheet will be required. The requirement to paper - good absorbency of the remains of oil which will remain after an extraction in the centrifuge.

6. In production inadmissibly the oil rest on softgel softgel capsules, after drying all softgel softgel capsules by small parties are washed out in the same centrifuge, but with isopropyl alcohol. In the takeup block fill up 50% of volume of softgel softgel capsules and fill in with isopropyl alcohol, further turn on the centrifuge and wring out alcohol, a part of alcohol evaporates, a part merges in a subsoil of the washing machine for reuse. The softgel softgel capsules which are washed out by alcohol get from the washing machine, alcohol quickly disappears. The feature of use of isopropyl alcohol is that it after evaporation does not leave marks of its application (color, a smell, taste) is completely harmless. This alcohol not for the food purposes perfectly dissolves oil. Over time alcohol will be sated with the remains of oil and it will be required to utilize it, and in the washing machine to use new. Requirements to the room for washing of softgel softgel capsules. Room temperature, without conditioning. Extract and use of safe electrical systems.

7. Calibration is used only for following to State standard specification. Through any sieve sift softgel softgel capsules, the first use a sieve with smaller, than it is required by diameter of a window, eliminating small marriage, further use a sieve with larger windows. Calibration of softgel softgel capsules up to 2 000 000 pieces a month becomes in the manual mode. At very biased requirements to quality all softgel softgel capsules still can undergo visual control by the operator. Each capsule is looked through on a special glass little table with illumination. Viewing will reveal the softgel softgel capsules rejected, not filled with substance.

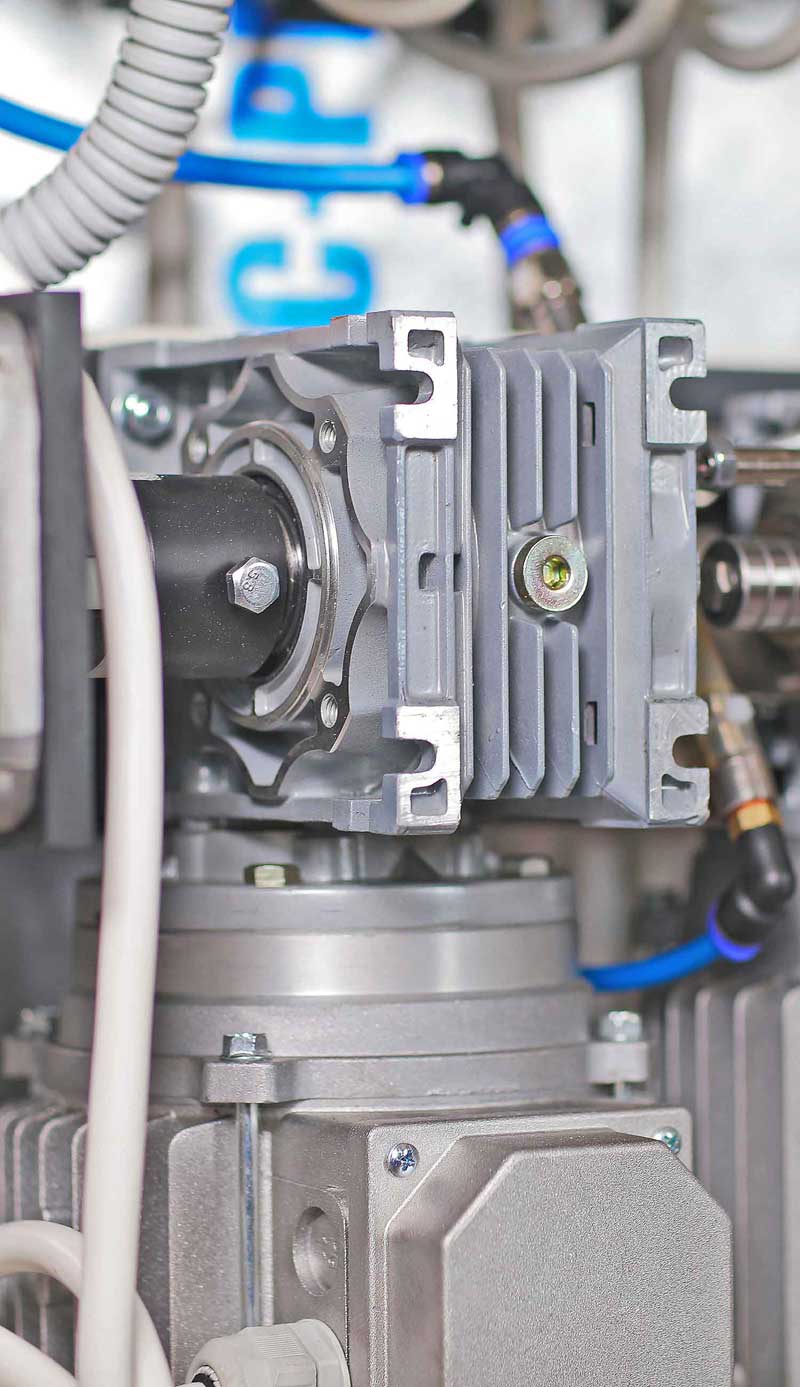

8. It is recommended to store in tight packing, at the room temperature in the dark room. In avoidance of adhesion and deformation of ready softgel softgel capsules it is recommended to store in the packaged look. And after calibration or just after drying to package in packing. A period of storage of gelatin softgel softgel capsules up to 2 years. In the course of work hit in the Encapsulator system of portions of substance which sates oil and dilutes it is possible. When carrying out scheduled maintenance it is required to make replacement of transport oil on new once a week. As we see special devices which it will be required to buy not much. All devices of household purpose and their quantity and cost depends on your budget. Encapsulator remains the most technologically difficult device.