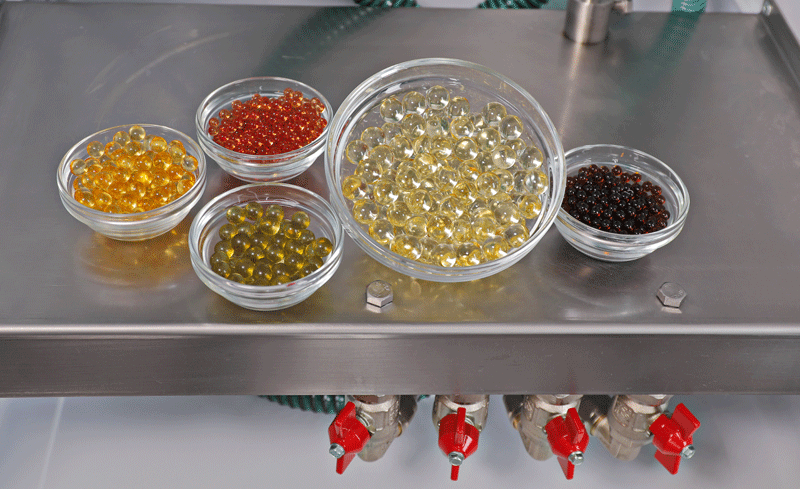

Encapsulator. Description. Soft gelatin seamless softgel capsules can is stored in appropriate conditions up to 3 years. The technology offered by us where as a cover of future capsule liquid gelatinous weight is used, and the received softgel capsules - soft seamless, spherical shape. When using similar technology there is an opportunity to regulate thickness of a wall of a gelatinous cover, diameter ready and the volume of filling of a gelatin capsule. The equipment makes only round softgel capsules. Diameter of softgel capsules can be adjusted from 2 mm to 10 mm. Outside a thin, but strong cover from gelatin, inside liquid oil. In the capsule there can be only an oil or liquid which is not destroying gelatin.

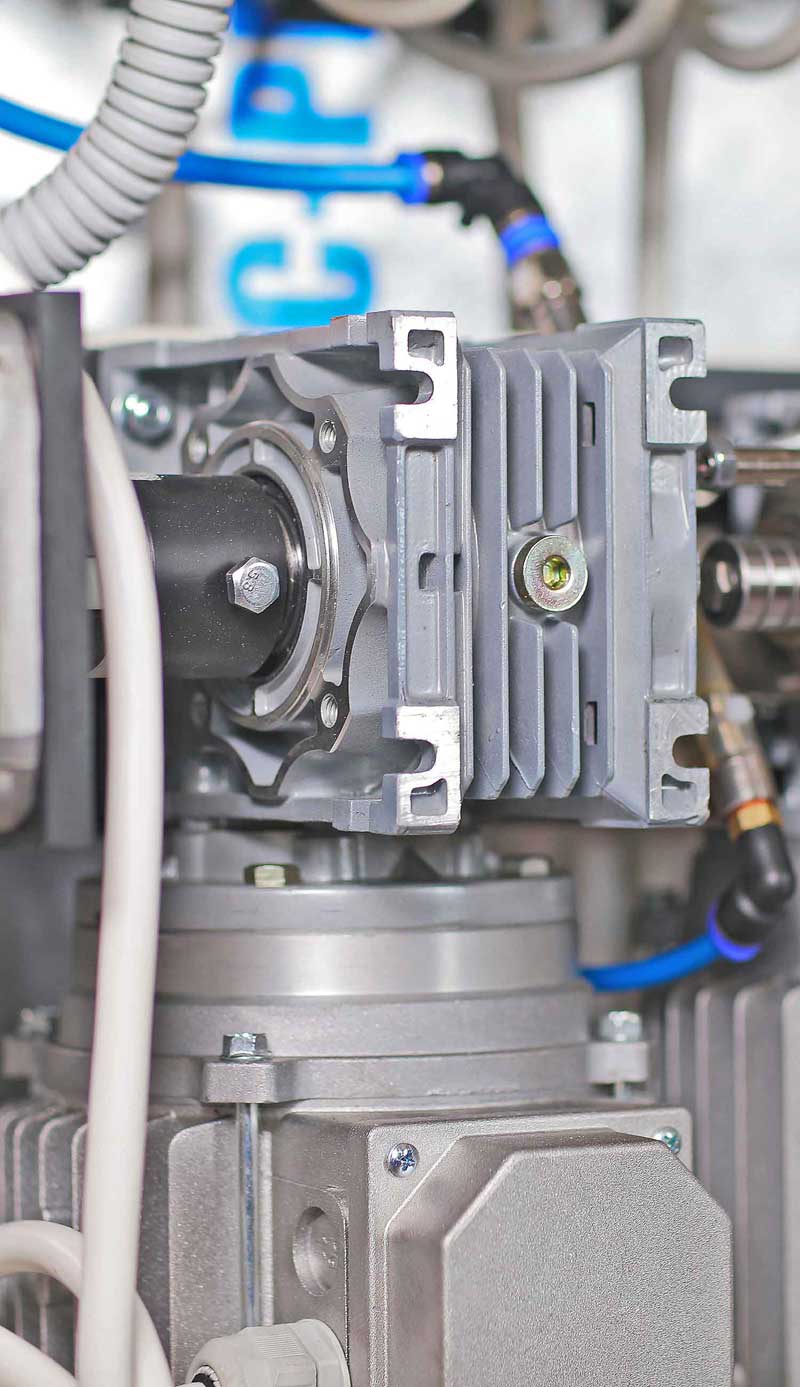

The Encapsulator device consists of such main knots and details: Completely tight case isolating from influence of the environment; Pump of transport vegetable oil; The Pulsator - creates oil pulsations; System of hoses and gates; The Refrigerating unit and the refrigerator - provide cooling of transport oil in the Encapsulator system; The LHC with heating elements serves for heating of gelatinous weight; Block of heads of formation of softgel capsules; Electronic blocks of thermal regulation and stabilization of temperature in the refrigerator and a tank of heating of gelatinous weight; System of supply of compressed air; Panel and control unit.

TECHNICAL CHARACTERISTICS:

Diameter of softgel capsules is from 2 to 15 mm

The frequency of pulsations regulated 1,2,3,4,5 impulses \second

Temperature of a warming up of a liquid gelatinous cover of 60-70 degrees With

Temperature of filler is 12-40 degrees With

Filling of softgel capsules adjustable from 0,05 to 0,4 grams

Oil pressure in a pulsator of 0.5-1.5 kg \cm

Power is 1,5 Kw

Food 220V

Overall dimensions of 700х600х2000 mm

Weight is 200 kg, with packing of 250 kg.

Installation is powered from the alternating current main, of 220 volts. Productivity of Encapsulator is up to 15000 softgel capsules per 1 hour. The production cycle since the beginning of capsulation before packing makes 2-3 days. The production site, numbering 5 people is capable to produce 1,5 million softgel capsules a month. Production of soft seamless gelatin softgel capsules is based on physical properties of gelatinous weight. Formation of softgel capsules comes at the exit from a head of Encapsulator in which under pressure of air filler and gelatinous weight moves. Under the influence of the pulsing oil in a head the stream is divided and at the expense of forces of a superficial tension of gelatinous weight the separated part smoothly takes spherical shape. The created capsule gradually stiffens in a low flow of the cooled vegetable oil. After formation of the capsule on the pipeline come to a baking sheet with the vegetable oil located on the regiment Encapsulator Consumption of Filler and Gelatinous Weight it is regulated. At the same time receive softgel capsules weighing filler from 0,05 to 0,4 grams. Oil pulsation frequency is equal in a head to the number of the created softgel capsules and in the course of a production cycle is stable, but depending on the mass of filler can be changed from 60 to 250 softgel capsules a minute. The room is equipped with the device for preparation of gelatinous weight, capacities for filler solution preparation, electronic scales. The device for preparation of gelatinous weight is equipped with the mixer and container with water in which the set temperature is automatically maintained. Solution of filler is prepared according to technological instructions. The prepared gelatinous weight and filler in necessary quantities are weighed and filled in in Encapsulator tanks. After inclusion of Encapsulator transport oil in system is cooled. The exit to "mode" takes about 10 minutes. During this time the Encapsulator operator adjusts formation of softgel capsules and their necessary dosage. In process of filling baking sheets change, moving on the lower regiments Encapsulator. The room of an extraction of softgel capsules from vegetable oil, is equipped with the centrifuge for an extraction and a sink for washing of baking sheets from vegetable oil. At the small volumes productions there is a manual method of an extraction excluding the centrifuge for an extraction. After an extraction of the capsule transfer to the site of drying. The room of drying of soft gelatin softgel capsules equipped with the conditioner with the air dryer and shelves on which place baking sheets with damp softgel capsules after an extraction. At the correct observance of the modes of temperature and humidity of the capsule dry in 24 hours. The dried-up softgel capsules from baking sheets pour in capacity and transfer to washing with isopropyl alcohol. The room of washing of softgel capsules, is equipped with capacity for isopropyl alcohol and the centrifuge for washing of the dried-up softgel capsules from the remains of vegetable oil. Obligatory existence of the exhaust ventilation. Softgel capsules fill up in a drum of the centrifuge in which via the gate a scattered stream isopropyl alcohol moves from capacity. At the small volumes productions there is a manual method of washing excluding the centrifuge.