Often it is difficult for our clients to understand precedence of purchase of the equipment connected with the organization of production of seamless gelatin softgel capsules. Therefore, for the purpose of minimization of expenses of means and time, we suggest to study our recommendations. Divide investment of production of softgel capsules into several stages. A stage first - purchase only of one Encapsulator and training. At this stage your expenses will make 14000 euros + funds for training and the expert's call to the location of your production. Time is required to understand all subtleties of technological process. When you realize all cycle of production of gelatin softgel capsules, you will easily pick up that equipment which is required in this technology. A stage second - production development. When you learn to cook gelatin, to control its properties and qualities, receive ready softgel capsules, dry up them and you will wash out from the oil rest, you will be able to understand what and in what quantities you buy the additional equipment. It does not make sense to hurry in this case.

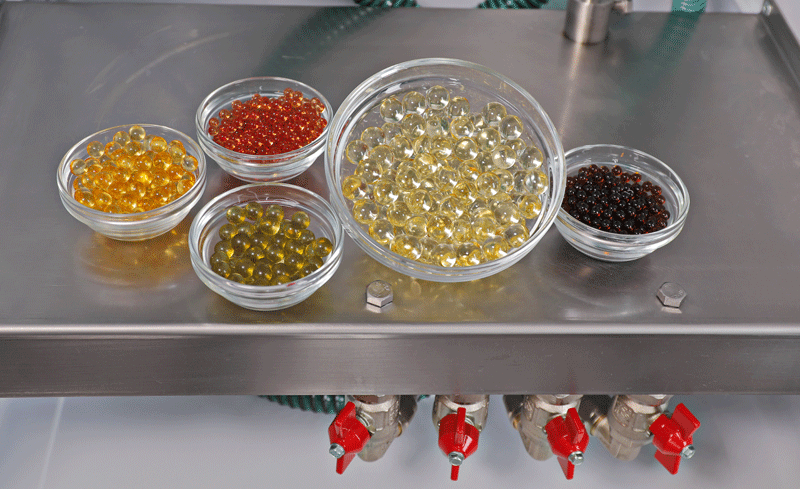

Calculation of quantity of kapsulyator for production of the required quantity of soft gelatin softgel capsules. One Encapsulator does not give the chance of an exit to wholesale production of softgel capsules. Usually our clients buy from 3 to 8 kapsulyator. If you plan to make the wide range of softgel capsules, then we advise on each type of production to have the Encapsulator. Also take into consideration that Encapsulator periodically should be stopped for a sink. When you plan the packing equipment, it is necessary to understand that soft gelatin softgel capsules can be packed up in blisterny packing or plastic and glass jars. If you imt calculations of productivity of kapsulyator, then will be able to receive productivity of the packing equipment. We will help with the choice of blisterny and packing cars. The equipment has the compact sizes and can be served by one operator. The Encapsulator case has continuous cooling inside and a door from glass, for visual control of processes. The operator makes all processes of setup of the equipment manually, visually controlling result. Process of start of the equipment takes from 5 to 10 minutes. In the subsequent the equipment can work without stopping 24 hours within 2 weeks.

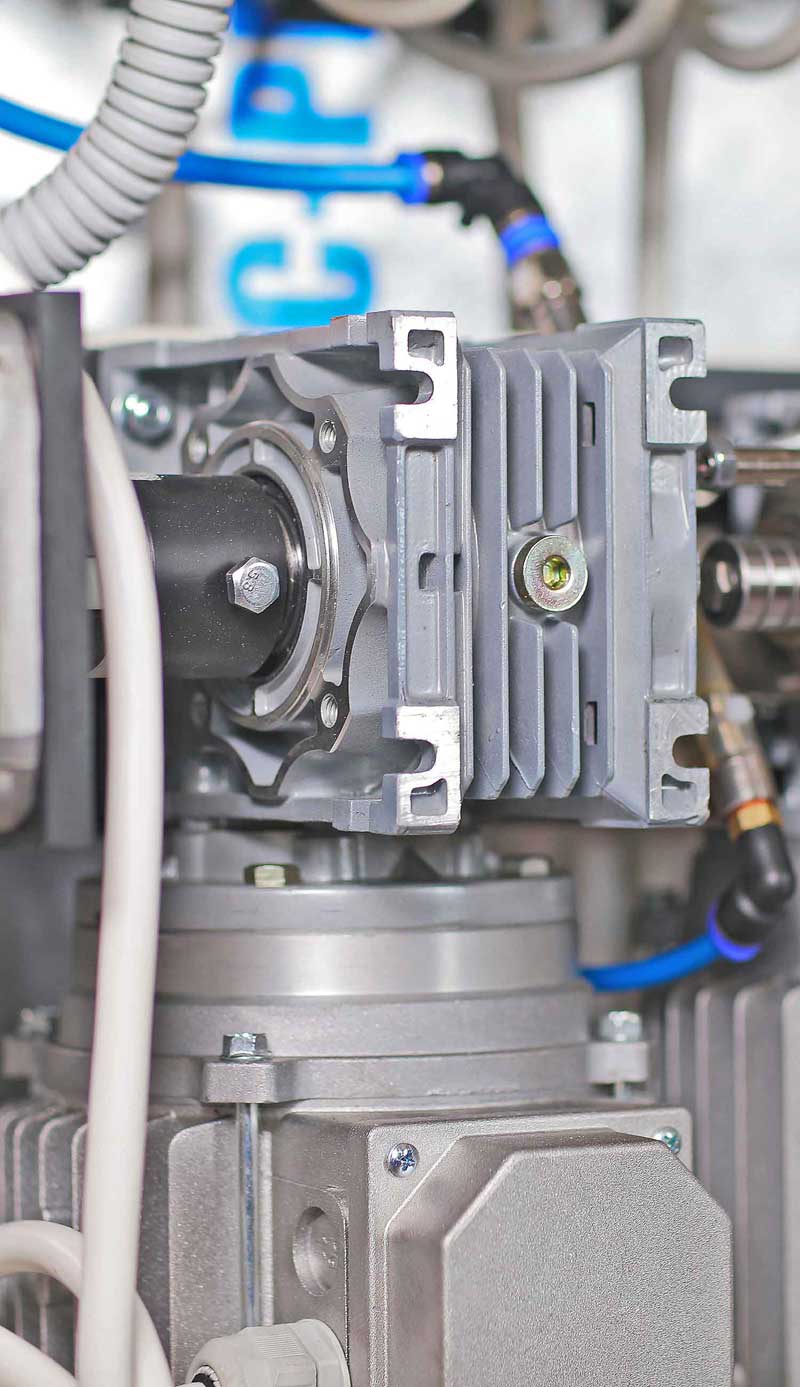

Compressed air or cylinder with gas Nitrogen is necessary for operation of the equipment. Popularly among our clients use of the air compressor. Training of personnel is the most important task which our client has to solve. The equipment has own cooling system of technological oil. At observance of our recommendations about the organization of production we guarantee quality of production. Process of operation of the equipment demands to carry out a stop of production of softgel capsules and a sink of all parts having contact with gelatin and oil. Stop periods once a month. In the course of production of softgel capsules technical oil absorbs moisture from air and over time its replacement is required. Control of need of replacement of oil on turbidity. After passing via the cooling system in transport oil ready softgel capsules need to be placed in the refrigerator for 24 hours. It is easy to sort all knots and details of the equipment for a sink and replacement. Convenient arrangement of governing bodies and control. The equipment has the electric system of heating of gelatin and filler with maintenance of the set temperature.

All parts which are in contact with gelatin and oil are made of stainless steel 304-316, bronze and other materials admissible in pharmaceutical production. The technology applied by us allows to receive gelatin softgel capsules, absolutely identical by the size, weight, a form. The term of operation of the equipment in the intensive mode - 5 years. In the equipment the necessary humidity and temperature is maintained by the built-in compressor. The built-in regulator of turns can be operated the speed of production of softgel capsules. By production of gelatin softgel capsules of the greatest possible size we recommend to reduce productivity. By production of the minimum size of softgel capsules it is possible to increase productivity. Advantage of the equipment is the high efficiency of the line, use of cheap raw materials and lack of waste. The equipment allows to regulate amount of oil inside, the capsule size, cover thickness.