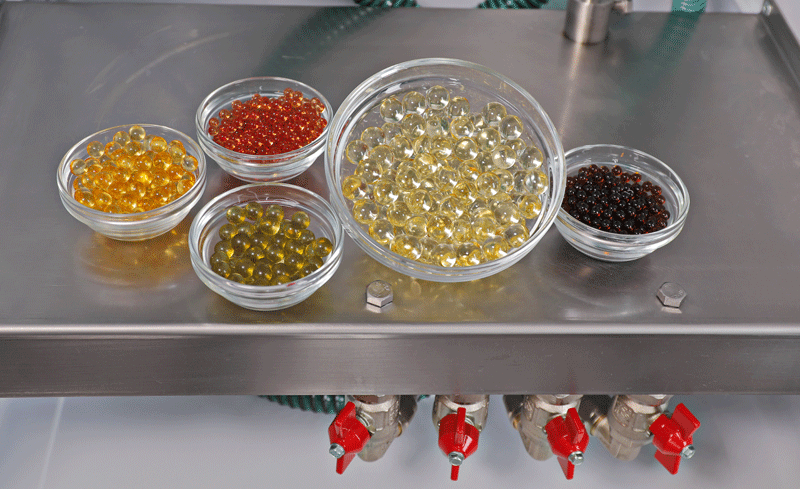

Production rooms and the description of technological process by production of soft seamless gelatin softgel capsules: site of preparation of substance of filler and gelatinous weight. The room is equipped with the device for preparation of gelatinous weight, capacities for filler solution preparation, electronic scales. The device for preparation of gelatinous weight is equipped with the mixer and container with water in which the set temperature is automatically maintained. First of all prepare glycerin solution with nipaginy. Glycerin gives elasticity to softgel capsules, and nipagin serves as preservative. Glycerin in the device is heated to +70 °C and at the switched-on mixer added nipagin. On 10,0 kilograms of glycerin add 141,0 grams of a nipagin. Solution mixes up before full dissolution 1,5 – 2 hours. new weight mixes up 1,5 hours before full dissolution, and then at the switched-off mixer 0,5 – 1,5 hours are defended. After that gelatinous weight is filtered through a kapron sieve and the viscometer measures viscosity. The viscosity of gelatinous weight has to be within 55 – 75 seconds. If indications do not meet standard, recalculation of ratios of water and gelatin becomes. Solution of filler is prepared according to technological instructions. The prepared gelatinous weight and filler in necessary quantities are weighed and filled in in Encapsulator tanks.

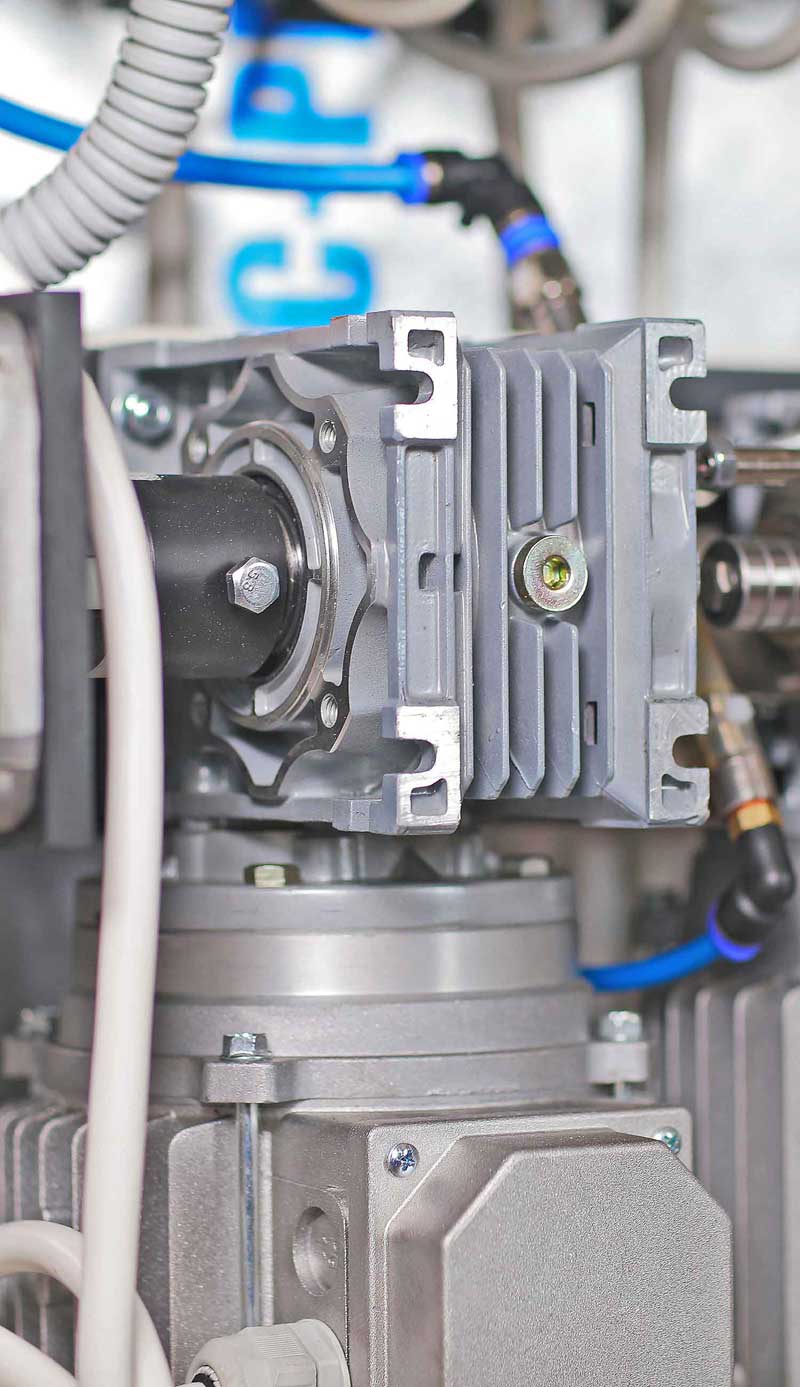

The site of capsulation in which Encapsulator is located is equipped with the conditioner. Air temperature on the site has to be in limits +18 … +22 °C, relative humidity of 55-75%. During the work on a kapsulyator with the untight case above 23 °C in the course of capsulation lead temperature increase on the site to sharp turbidity of transport vegetable oil owing to formation of condensate on the cooled Encapsulator hubs. The greatest accumulation of condensate is observed on a tray of an exit of softgel capsules from the Encapsulator refrigerator. Especially it comes to light during the summer period. After inclusion of Encapsulator transport oil in system is cooled to +10 … +12 °C in 30-40 minutes. In a baking sheet for softgel capsules fill in about 2 liters of vegetable oil. The exit to "mode" takes about 10 minutes. During this time the Encapsulator operator adjusts formation of softgel capsules and their necessary dosage. In process of filling baking sheets change, moving them to the refrigerator. In the course of capsulation, for control of a dosage each 10 – 15 minutes the doser weighs softgel capsules on electronic scales. For the accuracy of indications it is desirable to weigh 10 softgel capsules. Softgel capsules wash out under the local exhaust ventilation in a cup with air and weigh their gross weight. Then from softgel capsules extract filler, wash out a cover in a cup with air and weigh on electronic scales. On the difference of gross weight of softgel capsules and weight of a gelatinous cover calculate filler weight. Depending on the controlled weight of softgel capsules the Encapsulator operator can change the weight of filler or a gelatinous cover in the course of capsulation. After capsulation baking sheets with softgel capsules place in the refrigerator.

The refrigerator, is equipped with the conditioner. Air temperature in the camera within +5.+10 °C, relative humidity of 55-75%. The room is equipped with shelves on which place full baking sheets with softgel capsules in the course of capsulation. Softgel capsules in baking sheets defend within 24 hours, and then transfer to the site of an extraction. Site of an extraction of softgel capsules: the room of an extraction of softgel capsules from vegetable oil, is equipped with the centrifuge for an extraction and a sink for washing of baking sheets from vegetable oil. After an extraction of the capsule transfer to the site of drying.

The site of drying of soft gelatin softgel capsules, is equipped with the conditioner with the air dryer. Air temperature indoors in the course of drying changes from +20 to +30 °C. The room is equipped with shelves on which place baking sheets with damp softgel capsules after an extraction. Each baking sheet is previously dimmed the parchment paper preventing sticking of softgel capsules. Damp softgel capsules on baking sheets in order to avoid pasting place in one layer. In the course of drying of the capsule carefully mix each hour. At the correct observance of the modes of temperature and humidity of the capsule dry in 24 hours. The dried-up softgel capsules from baking sheets pour in capacity and transfer to the site of washing with isopropyl alcohol. Site of washing of softgel capsules with isopropyl alcohol: it is equipped with capacity for isopropyl alcohol and the centrifuge for washing of the dried-up softgel capsules from the remains of vegetable oil. Obligatory existence of the exhaust ventilation. Softgel capsules fill up in a drum of the centrifuge in which via the gate a scattered stream isopropyl alcohol moves from capacity. Washing happens in 30 seconds. In 15 liters of isopropyl alcohol wash out up to 80 kilograms of softgel capsules. After washing of the capsule in capacities transfer to the site of calibration and viewing.

The site of calibration and viewing of soft gelatin softgel capsules, is equipped with viewing tables with illumination. After washing of the capsule calibrate with the help sit with openings of a certain diameter. It is necessary for rejection of softgel capsules with deviations from average weight. Then softgel capsules are looked through on viewing tables with illumination. Softgel capsules have to be a round form, without smudges, not have mechanical damages and vials of air. After viewing of the capsule in capacities transfer to the site of packing. Packing of softgel capsules is carried out in blisters, or in glass or polyethylene jars with covers. All rooms have to have exchange ventilation with purification of air.